When Benjamin Franklin flew a kite during a thunderstorm, he proved that lightning consisted of electricity, giving rise to a massive industry, what we today call the power sector!

Later, Nikola Tesla made numerous advancements and today, the power sector is the backbone of modern civilization, delivering the lifeblood of electricity that fuels our homes, businesses, and vital infrastructure. The importance of electricity could be guessed by the megawatts of power generation capacity the nation has installed. As per the data on 31.05.2023, India has 4.17668 lacs MW of generation capacity. [gov]

However, this humongous resource comes with inborn risks. The workforce involved in the sector is prone to inherent dangers associated with high-voltage electricity and complex machinery. Thus, maintaining the highest levels of safety for workers across the industry, from engineers to field technicians, is inevitable. Well, making these safety protocols a cakewalk is now proven what was once only imagined.

You won’t believe how XR technology could transform these complex safety protocols into a breeze. Other enterprise sectors are already witnessing the change, and now the Power sector is up for the transformation. We are here listing some of the powerful ways of XR in Power—A read that you would never want to miss.

1. Immersive Training Simulations

Power plants are complex environments with numerous potential hazards. XR can simulate these environments, allowing workers to identify and respond to hazards in real time without being exposed to actual danger.

Data suggests that VR training is less expensive than regular training programs. Also, it is 4 times faster and 76% more effective than traditional methods. [Hitachi]

2. Real-Time Risk Assessments

Maintenance and inspection tasks in power plants often require entering hazardous areas. XR enables remote inspections, allowing experts to guide on-site personnel through complex procedures from a safe distance.

The solution even reduces training time by 40% and improves safety standards through hands-on experience. [OEM Update]

3. Interactive Safety Protocols

XR applications offer interactive safety protocols, such as virtual safety briefings and interactive checklists, changing the way employee engagement and reinforcing safety practices are practised.

Moreover, this type of training helps workers develop muscle memory and quick decision-making skills, which are essential during real emergencies. It also allows them to practise and refine their responses to different types of incidents.

4. Remote Assistance and Collaboration

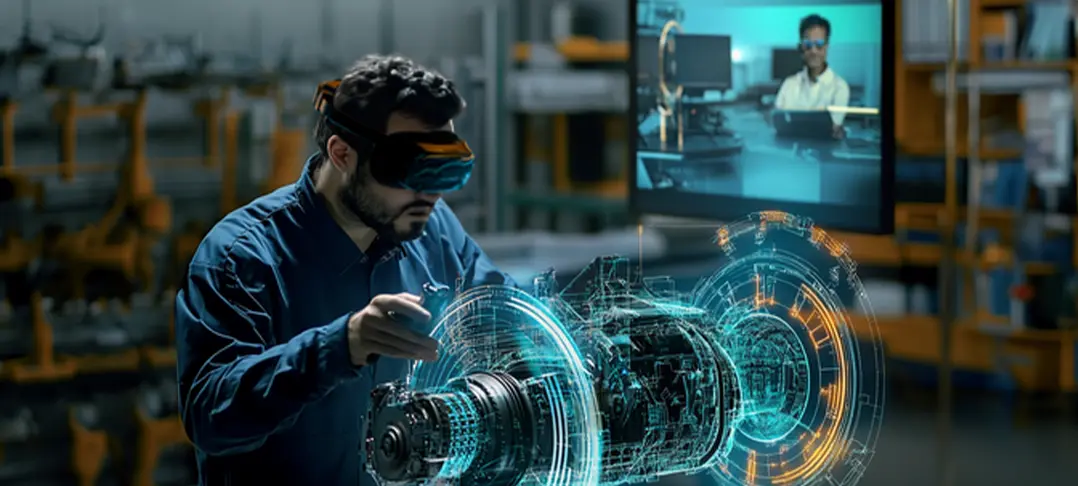

XR technology enhances remote assistance and collaboration by allowing experts to provide real-time guidance to on-site workers through augmented reality (AR) overlays.

This feature transforms communication, facilitating remote inspections and streamlining maintenance activities, ultimately improving safety outcomes and operational efficiency.

5. Data-Driven Safety Analytics

Understanding the intricate details of power plant equipment and systems is essential for safe operation and maintenance. XR provides detailed 3D visualisations of equipment, allowing workers to explore and understand its inner workings. It also helps identify potential issues before they become critical, enabling proactive maintenance.

NTPC has incorporated VR technology into their training programs, providing trainees with immersive 3D experiences. These VR modules allow trainees to interact with machinery in a virtual environment, eliminating the risk of damage or injury. [NTPC]

Enjoyed the blog? Share it with your network and spark a conversation!